Fields of application of muffler software

Acoustic consultancy and design

The muffler software is interesting for you if you are a consulting engineer who acoustically applies and designs various systems of silencers and mufflers to achieve a legally required or appropriate noise reduction of sound emitting devices and machines. Typically, systems of silencers and mufflers are applied in areas such as:

- intake and exhaust systems, turbolader of

- maschines and devices

- air-water-heat pumps (LWWP) and cogeneration units (BHKW)

- automobiles (Pkw), motorcycles and trucks (Lkw)

- rail vehicles

- ships

- power plants

- ventilation systems, air conditioning systems

- ducts with flow

Numerous ready-made components of silencers and mufflers typically applied in industry are available, for example:

- absorption mufflers

- reflection mufflers

- resonance mufflers

- duct elements

- specific installations

By choosing the right geometrical parameters and material parameters, the system of mufflers can be optimized by you with respect to the given acoustical requirements. By flexible combination of single components, geometrically complex silencers and mufflers can be designed as well.

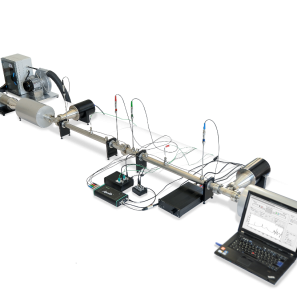

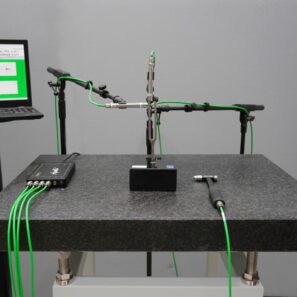

The application of a specific program option enables the efficient acoustic test of new sound absorbing materials by evaluating the absorber material parameters directly measured with the help of transmission tube AcoustiTube®.

Fabrication of mufflers and silencers

The muffler software is also very helpful to you if you are a manufacturer who develops, fabricates and distributes collections of components of silencers and mufflers that are to be efficiently applicable to a wide operational range. In this case, mathematical descriptions to simulate the acoustic efficiency of your own business-specific components can be developed and implemented.

The muffler software gives you the following advantages:

- It enables you to create a house-intern product database containing the acoustic behavior of every single component. So you can always easily choose the right component to meet the specific requirements. On demand, we adjust our data structure to your products as well.

- The accuracy of predicting the acoustic efficiency of your specific components of mufflers can be optimized by acoustic measurements at fabricated components. The measurement results are directly applied to the customized computation model. These adjustments are specific to your fabrication granting you exclusive access to them.

Technical Data

Absorption mufflers

Resonance mufflers

lambda/4-resonance muffler with branch line / with resonance core probe

lambda/4-resonance muffler with resonance chamber

Helmholtz resonance muffler with branch line / with resonance chamber Reflection mufflers

Catalytic elements

variable number of transmission tubes filled with catalytic material, e. g. SCR, DOC Duct elements

Straight duct

Linear change of cross section

Exponential change of cross section Special elements

Module for import arbitrary transfer matrix, determined e. g. by numerical simulation or by direct measurement in the test setup for silencers and muffler