Fields of application of test setup for mufflers

Among other things, the operational area of the measuring system includes:

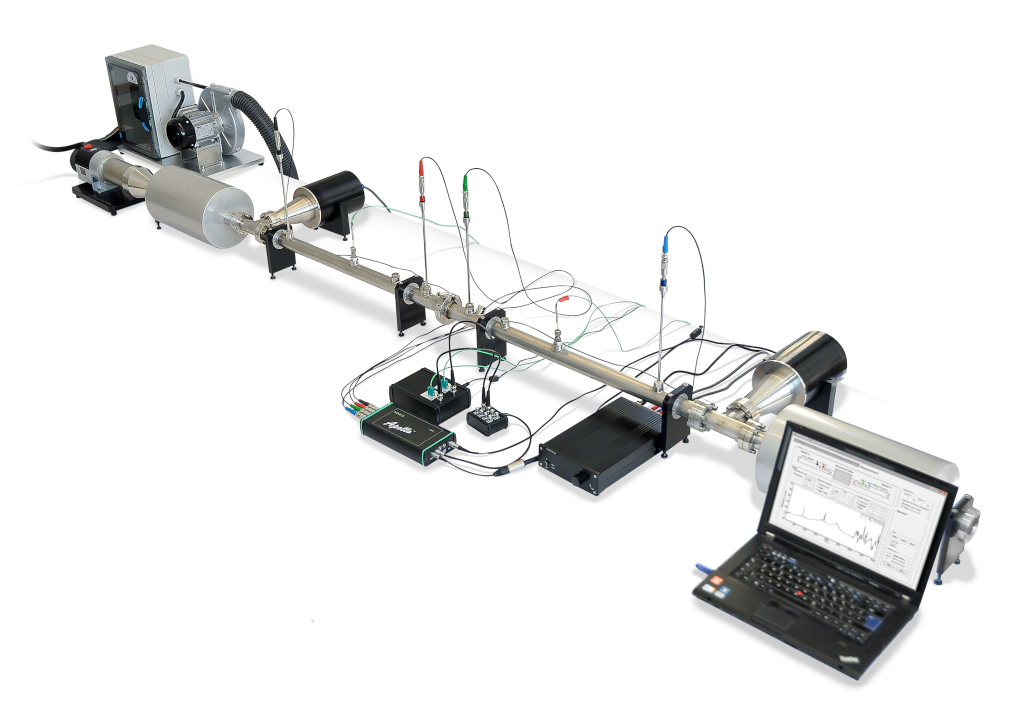

- test setup for mufflers (suitable for application in the laboratory as well)

- measurement of the spectral transmission loss of silencers and mufflers at high temperatures in a transmission tube

- application of measurement data as input parameters for calculating the spectral transmission loss and the spectral insertion loss of complete systems of silencers and mufflers by means of the analysis software AcoustiCalc® Silencer (consideration of peripheral components, e. g. installation of a measured muffler within a complete exhaust system)

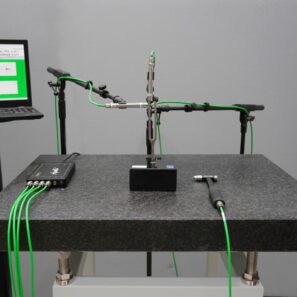

- application of measuring device as impedance tube

Software

The test setup for mufflers and silencers is supported by the analysis software AcoustiStudio – Module Sound Transmission.

- applicaton of the Two Source Method with 4 microphones for determining the transmission loss and the transfer matrix of silencers and mufflers as a function of frequency

- alternative applicaton of the Two Load Method with 4 microphones for determining the transmission loss and the transfer matrix of silencers and mufflers

- alternative measurement of transmission loss of silencers and mufflers according to DIN EN ISO 11820

- comfortable storage and management of measurement data in database system

- direct comparison of measurement results with simulation results of the muffler software AcoustiCalc® Silencer

- calculation of third octave band spectra, octave band spectra and average values

Technical Data

Transmission tube system

- consisting of each 2 measuring units, speakers and mufflers

- robust construction

- temperature durability of all components: up to 600 °C

- system diameter

- type 1

- inner diameter: 66 mm

- frequency range, fluid temperature 20 °C:

ca. 30 Hz to 3.000 Hz- frequency range, fluid temperature 600 °C:

ca. 50 Hz to 5.200 Hz

- type 2

- inner diameter: 38 mm

- frequency range, fluid temperature 20 °C:

ca. 30 Hz to 5.300 Hz- frequency range, fluid temperature 600 °C:

ca. 50 Hz to 9.100 Hz- 4 selectable positions for microphone probes per measuring unit

Heating system

- consisting of heater and ventilator

- independent feedback control system

- max. temperature: 650 °C (at the output of the heater)

- max. volume flow: 6.000 l/min (fluid temperature 20 °C, ventilator at 3.600 rpm)

Sensors

- 4 microphone probes

- 2 temperature probes